What is a Single-Sided Flexible PCB?For the immediate pressure, flexible circuits With its own coping style, it can break the predicament and usher in a new life through the quality of the product itself. https://gekunflex.com/

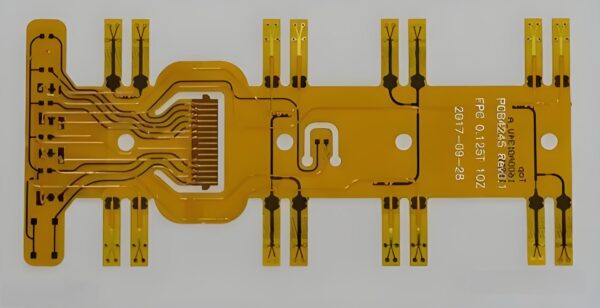

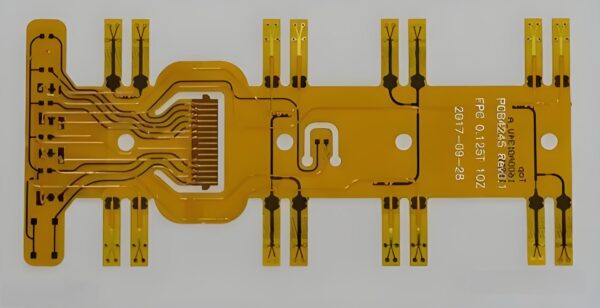

A single-sided flexible PCB consists of one conductive layer, usually made of copper, and a flexible substrate. It is designed for simple, low-complexity circuits where electrical components are mounted only on one side. Single-sided flexible PCBs are highly flexible, lightweight, and cost-effective, making them ideal for applications that require a flexible connection or movement in confined spaces.

Typical features of single-sided flexible PCBs include:

One conductive layer

Simple design and manufacturing process

Reduced cost due to fewer materials

Excellent flexibility, allowing bending and folding without compromising function

Single-sided flexible PCBs are widely used in consumer electronics, medical devices, and automotive sensors, where space and weight are critical factors.

What is a Double-Sided Flexible PCB?

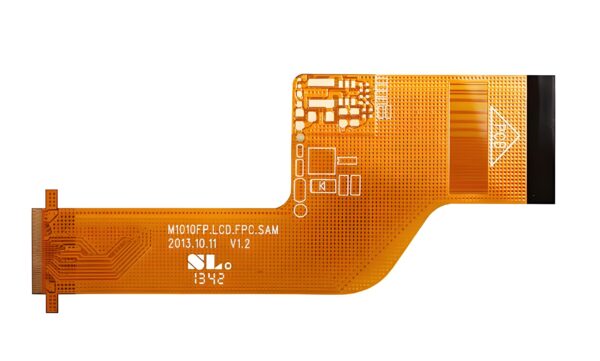

A double-sided flexible PCB has two conductive layers, one on each side of the flexible substrate. These layers are interconnected using vias (small plated holes), allowing more complex circuitry and higher component density than single-sided PCBs. The double-sided design offers enhanced functionality and flexibility for more advanced applications that require signal routing on both sides of the board.

Key features of double-sided flexible PCBs include:

Two conductive layers

More complex designs for higher functionality

Vias for inter-layer connectivity

Higher component density, supporting more complex circuits

Double-sided flexible PCBs are used in more sophisticated applications like industrial control systems, aerospace technology, and complex automotive electronics, where higher performance and reliability are required.

Single-Sided Flexible PCB

Key Differences Between Single-Sided and Double-Sided Flexible PCBs

The primary differences between single-sided and double-sided flexible PCBs are their layer structure, functionality, and applications.

Feature Single-Sided Flexible PCB Double-Sided Flexible PCB

Number of Conductive Layers One layer Two layers (one on each side)

Design Complexity Simple designs Supports more complex circuits

Manufacturing Cost Lower cost due to fewer materials Higher cost due to additional layers

Component Density Limited to one side Allows components on both sides

Applications Consumer electronics, sensors, medical Aerospace, automotive, industrial

Flexibility High flexibility Moderate flexibility

Applications in Various Industries

Single-sided flexible PCBs are commonly used in:

Consumer Electronics: Remote controls, LED lighting systems, and mobile devices, where simplicity and low cost are essential.

Automotive: Sensors and connectors that require lightweight and flexible designs.

Medical Devices: Wearable health monitors and portable medical equipment, where small, flexible circuits are needed.

Double-sided flexible PCBs find their place in more advanced applications, such as:

Aerospace: Flight control systems and avionics that require high-reliability, complex circuitry in lightweight formats.

Automotive: Engine control units, infotainment systems, and safety sensors.

Industrial Equipment: Robotics and machinery that demand multi-layer circuits with high performance and durability.

Choosing the Right Flexible PCB for Your Needs

Selecting between a single-sided or double-sided flexible PCB depends on the specific needs of your project. If your application requires a simple, low-cost solution with minimal circuitry, a single-sided flexible PCB is often sufficient. However, for more complex designs requiring higher functionality and component density, a double-sided flexible PCB is the better option.

Rigid-Flex Combination

Gekun: Your Trusted Flexible PCB Manufacturer

Whether you¨re looking for single-sided flexible PCBs for simple electronic applications or double-sided flexible PCBs for more advanced industrial or automotive projects, Gekun offers high-quality, reliable solutions. With our advanced manufacturing processes and commitment to innovation, we ensure that our products meet the highest standards for performance and durability. Partner with Gekun for your next project and experience the benefits of cutting-edge flexible PCB technology.

Understanding the differences between single-sided and double-sided flexible PCBs is essential when choosing the right solution for your application. Both types offer unique advantages and are tailored to meet the needs of various industries. As technology advances, flexible PCBs will continue to play a crucial role in the development of innovative electronics, automotive systems, and aerospace technologies.

For top-quality flexible PCBs, trust Gekun to deliver solutions that meet your specific needs, from design to production.