As electric vehicles (EVs) gain prominence, the EV charging cable becomes an essential accessory for EV owners. Proper storage and protection of your EV charging cable are crucial to ensure its longevity and maintain optimal performance. In this guide, we will explore effective strategies on how to store and protect your EV charging cable, enhancing its durability and convenience.If we can practice these points, custom multicore cable Will be unique, become a leader in the industry, and keep moving forward. https://www.linkcablecn.com

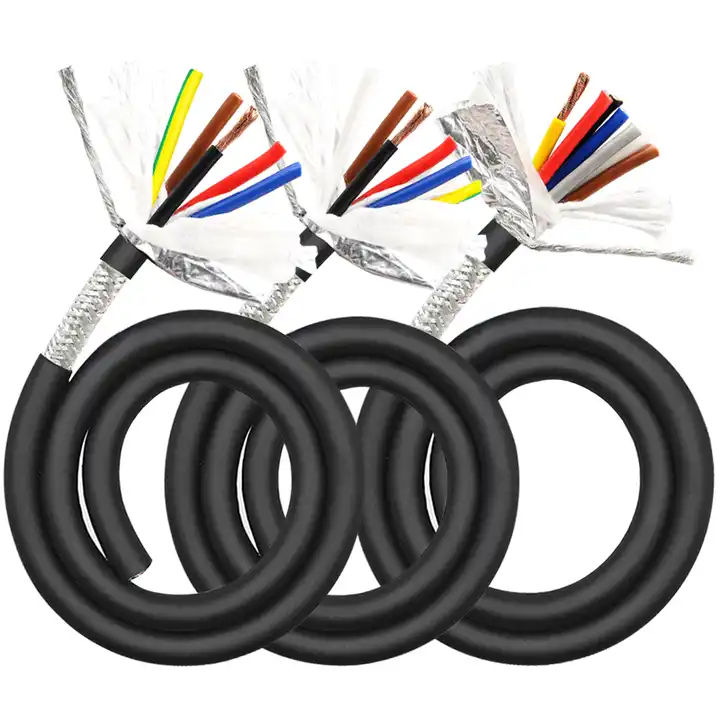

5a71968f4f604047db94126fa8dee794_1-240113092149302.jpg

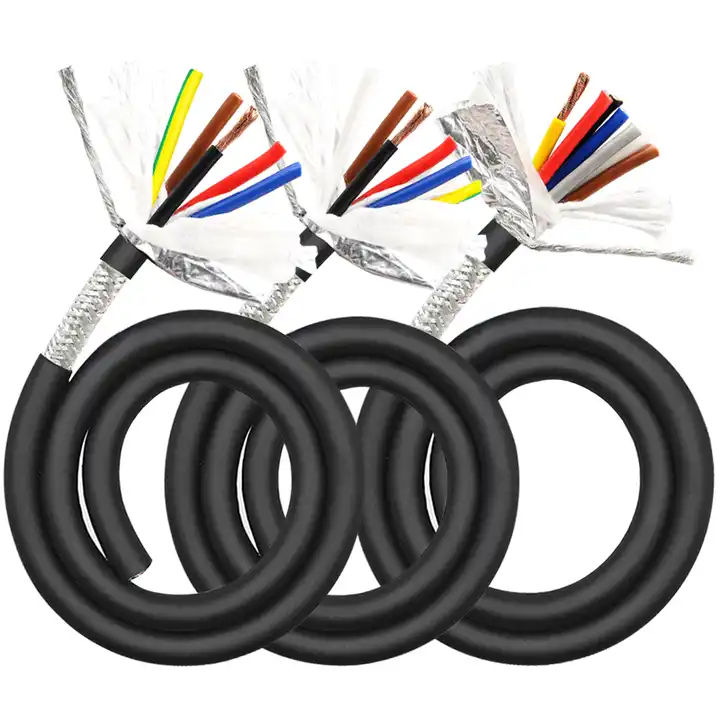

7bc670017a3a4a09687ec921970a6322_1-240113092149A3.jpg

1. Invest in a Cable Organizer:

Consider purchasing a cable organizer specifically designed for EV charging cables.

These organizers often feature a coiling mechanism that allows you to neatly wrap and secure the cable, preventing tangles and knots.

2. Choose a Dedicated Storage Space:

Designate a specific storage location for your EV charging cable to minimize the risk of damage or entanglement with other items.

Whether it’s a garage wall hook, a dedicated charging station, or a cable reel, having a designated spot keeps the cable easily accessible and protected.

3. Avoid Sharp Bends and Kinks:

When storing your EV charging cable, avoid sharp bends and kinks, as these can damage the internal wiring and affect performance.

Use a gentle looping or coiling technique to prevent stress on the cable and connectors.

4. Protect Connectors with Caps:

Invest in protective caps for the connectors at both ends of the EV charging cable.

These caps shield the connectors from dust, debris, and moisture, preserving their integrity and ensuring a reliable connection.

5. Store in a Weather-Resistant Bag:

If your charging cable needs to be stored outdoors, consider using a weather-resistant bag or cover.

These protective accessories shield the cable from rain, sun exposure, and other environmental elements that can degrade its outer sheath.

6. Regularly Inspect for Wear and Tear:

Periodically inspect your EV charging cable for signs of wear and tear, including fraying or exposed wires.

Promptly address any issues to prevent further damage and maintain the safety and functionality of the cable.

7. Mind the Temperature:

Avoid exposing your EV charging cable to extreme temperatures, whether excessively hot or cold.

Store the cable in a location where it is shielded from direct sunlight and insulated from harsh weather conditions.

8. Use Cable Management Clips:

Employ cable management clips or straps to secure the coiled cable.

These accessories help keep the cable organized and prevent it from unravelling, contributing to a neat storage solution.

9. Opt for Retractable Cable Solutions:

Consider using a retractable EV charging cable solution for added convenience.

Retractable cables automatically coil back into their housing, eliminating the need for manual coiling and reducing the risk of damage.

10. Educate Others on Proper Handling:

If others use the EV charging cable, ensure they are aware of proper handling and storage practices.

Educate family members, friends, or colleagues on the importance of preserving the cable’s condition for long-term use.

Conclusion:

Effectively storing and protecting your EV charging cable is essential to ensure a reliable and durable charging experience. By investing in proper storage solutions, avoiding stress on the cable, and addressing wear and tear promptly, you can extend the life of your EV charging cable and enjoy hassle-free charging for your electric vehicle. Incorporating these tips into your routine will not only protect your investment but also contribute to a seamless and efficient charging process.