Metal medal production is a well-made metal medal. According to different shapes, it can be divided into: medals, medals, and award plates. Common medal materials: made of aluminum, iron, zinc alloy, copper, gold, silver and other materials. There are also stone, wood, resin, organic, and even several kinds of composite materials.Even so, custom medals We must also adhere to the quality of the industry and create unique products for the company. https://www.karonmetal.com

Materials for making metal medals.

High-end medals:

1. Breakthrough in technology, make race medals custom in Shanghai Yibi Mint, use advanced and precise production technology and production process, so that this medal shows its original medal value orientation in high-end and uniqueness.

2. Breakthrough in design, exquisite design and technology, improve the value of the medal.

Process of making metal medals

In the medal making industry, what kind of production technology and production process are used to make the medal will make this medal show its original medal value orientation in high-end and uniqueness. Among them, the electroplating process is divided into many categories.

Electroplating process – chrome plating

Chromium is a silvery-white metal with a slight sky blue tint. The chrome layer has high hardness, good wear resistance, strong reflective ability, and good heat resistance. There is no obvious change in gloss and hardness below 500<C; it begins to oxidize and discolor when the temperature is greater than 500<C; it begins to soften when it is greater than 700<C. Due to the excellent performance of the chrome plating layer, it is widely used as a protective, decorative coating system’s surface layer and functional coating.

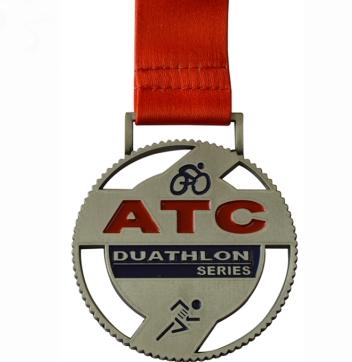

Custom made trophies and medals.jpg

Electroplating process – copper plating

Copper is easy to oxidize, and the oxidized patina is no longer conductive; copper plating is easy to lose its luster in the air, and reacts with carbon dioxide or chloride to form a layer of basic copper carbonate or copper chloride film on the surface. It will generate brown or black copper sulfide when it is exposed to sulfides. Therefore, as a decorative copper plating layer, an organic coating layer needs to be coated on the surface.

Price of metal medal production

The material is very important in the production of metal medals. One cent for one product has always been the value law of any industry and any commodity. It is difficult to get high-end products at a very low price.

Wholesale soft enamel sport medal.jpg

Details of metal medal production

In the daily production of high-end medals, there will be many details to be carefully improved. In addition to the main aspects, it is also necessary to pay attention to local details. For example, what style of medal wooden tray and what kind of medal back plate to match it should not be underestimated.

Dongguan Karon Hardware is committed to providing you with customized products such as medals and badges, mastering the core technology of customized badges and medals. In addition to medals and badges, the products produced include various commemorative coins, trophies, key chains, badges, crafts and other personalized hardware products. As long as you want, we can customize it. Creative design and excellent craftsmanship are perfectly combined to meet all your needs.