The flexible printed circuit (FPC) market in Europe and the US has witnessed rapid growth over the past decade, driven by the increasing demand for compact, lightweight, and highly flexible electronic solutions across industries. From consumer electronics to automotive, aerospace, and medical devices, flexible circuits have become an integral component of modern product design. But just how big is the flexible electronic circuit market in these regions?for a long time flexible PCB It has an extraordinary development speed, and I believe that the future will be as overwhelming as ever. https://gekunflex.com/

In this blog, we will explore the size, value, and future prospects of the European and US flexible electronic circuit market, examining its key drivers and opportunities for growth.

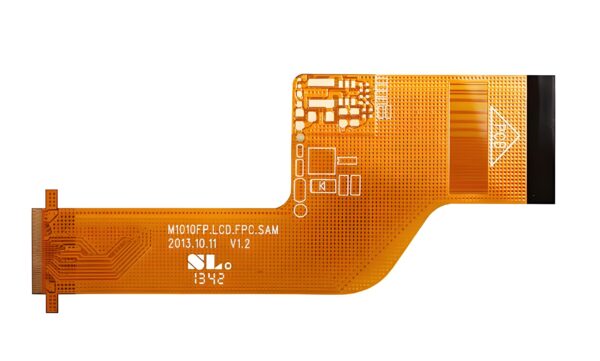

Flexible Printed Circuit

Flexible Printed Circuit

1. Introduction to the Flexible Printed Circuit Market

Flexible printed circuits (FPCs), often referred to as flexible electronic circuits, are critical components in various industries where space, weight, and performance are key factors. Their unique ability to bend and fold makes them ideal for a wide range of applications, from smartphones to medical devices and automotive electronics.

The European and US flexible electronic circuit markets are expanding significantly due to advancements in technology, with both regions leading the way in innovation and adoption. But how large is this market, and what factors are driving its growth?

2. The Current State of the Flexible Electronic Circuit Market in Europe

The flexible electronic circuit market in Europe has seen steady growth, especially in the automotive and industrial sectors. European countries, particularly Germany and the UK, have a strong manufacturing base in automotive electronics and industrial automation, which has fueled demand for flexible circuits. The push towards electric vehicles (EVs) and renewable energy technologies is further driving the need for flexible, efficient, and durable electronic circuits.

Automotive sector: The rise of electric vehicles (EVs) and autonomous driving technologies is creating new opportunities for flexible circuit manufacturers. Flexible circuits are used in various components, such as battery management systems, infotainment, and advanced driver assistance systems (ADAS).

Medical devices: Europe has a mature medical technology market that relies on compact and reliable electronic components. Flexible PCBs are used in wearable health monitors, imaging devices, and other high-precision medical equipment.

According to market research, the European flexible electronic circuit market is expected to grow at a compound annual growth rate (CAGR) of around 8% between 2023 and 2028. This growth is driven by increasing R&D investments and the region¨s focus on sustainability and innovation.

3. The US Flexible Circuit Market Overview

The US flexible electronic circuit market is one of the largest globally, with a strong focus on consumer electronics, aerospace, and defense applications. The high demand for miniaturization and lightweight components in these sectors makes flexible circuits an essential part of their electronics ecosystem.

Consumer electronics: The US is home to some of the world¨s largest consumer electronics companies, and the demand for flexible circuits in smartphones, tablets, and wearables is on the rise. Flexible circuits allow manufacturers to design thinner, lighter, and more complex devices that meet consumer expectations for portability and performance.

Aerospace and defense: In the aerospace sector, flexible PCBs are used in satellite communications, radar systems, and avionics. The US defense sector also relies on flexible circuits for rugged, mission-critical applications, such as drones, communication systems, and weapons technology.

With the US being a global technology leader, the US flexible circuit market is projected to continue growing at a significant pace, driven by innovations in 5G, IoT (Internet of Things), and smart devices.

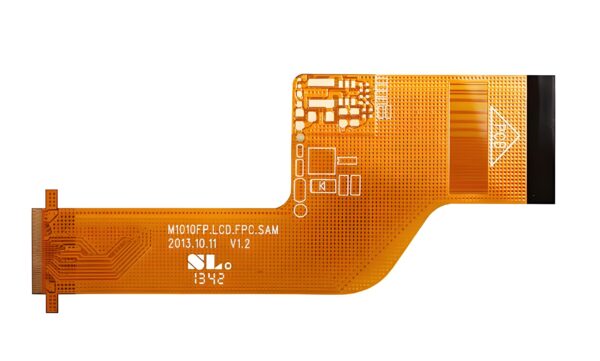

Flexible Printed Circuit

4. Key Growth Drivers in Europe and the US

The flexible electronic circuit markets in Europe and the US are being shaped by several key growth drivers:

Demand for miniaturization: The ongoing trend toward smaller, lighter, and more powerful devices is driving demand for flexible PCBs that can fit into tight spaces without compromising performance.

Automotive electronics: The automotive industry¨s transition to electric and autonomous vehicles is creating a surge in demand for reliable and efficient electronic components, including flexible circuits.

Medical technology: With the rise of telemedicine, remote monitoring, and wearable health devices, the demand for compact, flexible circuits is growing rapidly in the healthcare sector.

Environmental sustainability: Flexible circuits can contribute to more sustainable designs by reducing the weight and material consumption of electronic devices, which aligns with Europe¨s and the US¨s increasing focus on green technologies.

5. Emerging trends shaping the market

Several emerging trends are expected to influence the European and US flexible electronic circuit markets in the coming years:

5G Technology: The rollout of 5G networks will increase demand for flexible PCBs in communication devices, mobile phones, and base stations.

Wearable Technology: As wearable devices, such as smartwatches and fitness trackers, become more popular, the market for flexible circuits will expand further.

Flexible Displays: Flexible PCBs are essential in the development of flexible displays, which are increasingly used in smartphones, tablets, and even foldable laptops.

IoT (Internet of Things): As IoT devices proliferate, there will be a growing need for flexible circuits that can be integrated into a wide range of smart products.

Flexible Printed Circuit Market

6. Why Choose Gekun for Your Flexible Printed Circuit Needs?

At Gekun, we understand the specific demands of the European and US flexible electronic circuit markets. With our advanced manufacturing capabilities, we deliver high-quality flexible PCBs that meet the stringent requirements of industries like automotive, aerospace, and consumer electronics.

Our key advantages include:

State-of-the-art manufacturing processes that ensure reliability and performance.

Tailored solutions for different industries, from automotive to medical and aerospace.

Competitive pricing and flexible order quantities to suit your needs.

Whether you¨re in need of a prototype or full-scale production, Gekun is your trusted partner for flexible printed circuit solutions.

The flexible electronic circuit markets in Europe and the US are growing at a rapid pace, driven by innovations in automotive electronics, consumer devices, and medical technology. With advancements in 5G, IoT, and wearable technology, the demand for flexible circuits is expected to rise even further in the coming years.

For businesses looking to stay ahead of the curve in these competitive markets, choosing the right flexible circuit manufacturer is critical. With Gekun, you get a partner that delivers high-quality, cost-effective, and innovative solutions tailored to your industry¨s needs.

By understanding the flexible electronic circuit market dynamics in Europe and the US, you can make informed decisions and capitalize on growth opportunities in these key regions.