A hub docking station is an essential accessory for businesses that rely on efficient connectivity and streamlined workflows. While off-the-shelf models cater to general users, businesses often require tailored solutions to meet industry-specific demands. Customizing docking stations with specialized features such as unique port configurations, encryption, and enhanced heat dissipation can significantly enhance productivity and security.Even if there are obstacles to moving forward, best wireless hdmi supplier We should also persevere, forge ahead bravely, cut waves in the sea of the market, hang on to Yun Fan and strive for the first place. https://worldtypec.com/

1. How to Customize Docking Stations for Business Needs

Hub docking stations can be tailored to suit various business functions, ensuring better adaptability to specific environments:

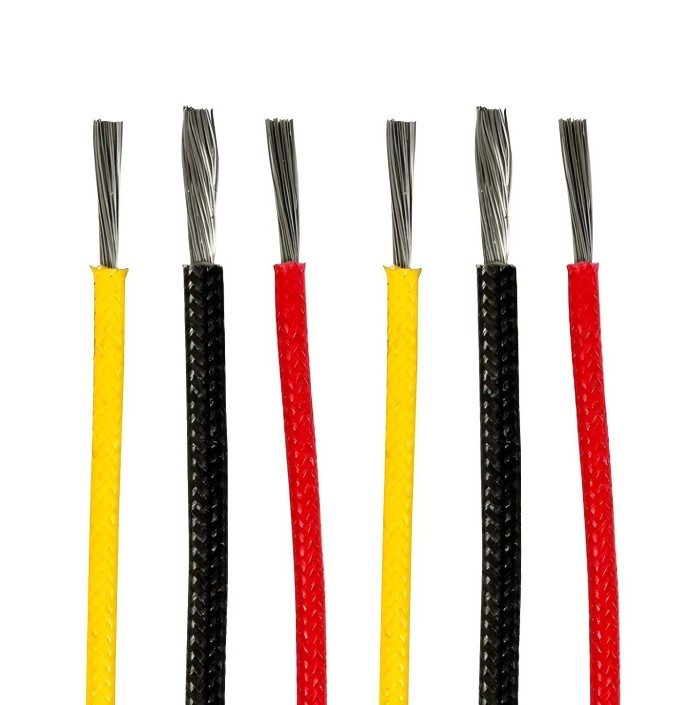

Port Configuration: Businesses often require unique port setups, such as additional USB-C ports, HDMI outputs, or Ethernet ports. For instance, creative industries might prioritize multiple 4K video outputs for multi-monitor setups, while IT environments may demand high-speed data transfer ports.

Encryption and Security: Data security is paramount in industries like healthcare and finance. Custom docking stations with built-in encryption or secure access control provide an added layer of protection against data breaches.

Heat Dissipation: High-performance devices generate significant heat. Advanced heat dissipation designs in custom docking stations ensure durability and stable operation, even in high-demand environments.

2. Industry-Specific Requirements

The unique demands of various industries highlight the need for customized hub docking stations:

Medical Industry: Hospitals and clinics require docking hubs that support secure, encrypted data transfer for sensitive patient information. Custom features such as biometric authentication or RFID support can further enhance security.

Education Industry: Educational institutions need multi-port docking stations compatible with a variety of devices like tablets, laptops, and projectors. A universal docking hub with broad compatibility can facilitate seamless learning experiences.

Creative Industry: Graphic designers and video editors often require docking stations with high-speed data ports and support for multiple displays at 4K resolution.

Corporate Offices: Businesses in any sector benefit from efficient enterprise docking hubs with optimized cable management and power delivery for a clutter-free, productive workspace.

HUB docking station.png

3. Worldpass for Custom Docking Solutions

Worldpass is a leading supplier of customizable hub docking stations, offering tailored solutions to meet the unique needs of businesses:

Comprehensive Customization: Worldpass provides businesses with the ability to select specific features, such as additional ports, enhanced heat dissipation, or encryption modules.

Industry Expertise: With years of experience, Worldpass understands the challenges different industries face and delivers docking stations designed to solve real-world problems.

High-Quality Manufacturing: Each docking station is built to last, ensuring stable performance and reliability in demanding business environments.

Customizing hub docking stations allows businesses to address industry-specific requirements, enhance security, and improve operational efficiency. From multi-port configurations to advanced heat dissipation, tailored solutions ensure businesses get exactly what they need.

Worldpass specializes in providing custom docking stations for enterprises, offering reliable, scalable, and secure solutions for various industries. Invest in a custom hub docking station today to elevate your business’s connectivity and performance.

” target=_blank>

” target=_blank>